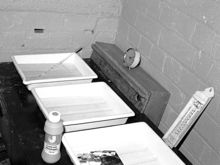

I’ve been amusing myself this evening scanning old black & white negatives and colour slides into the computer: strips of film that have languished in negative files on top of cupboards for years. It’s a boring process, but punctuated with the reward of finding something I thought was lost, or a negative that was never printed.

Some of the pictures go back to 1973, and are an unwelcome reminder of my antediluvian origins. But they’re also revealing of the state of technology at the time, and what I was doing with it. All the black and white pictures in this post are from the archive.

The photographic process itself is a prime example: the relative time and cost of developing and printing my own films being one reason many pictures haven’t been properly seen until now.

Things sure have moved on. I asked my 15 year old nephew if he’d ever used film, and after clarifying I didn’t mean video tape, he confirmed he’d never touched the stuff. Silly of me to ask really.

Regrettably, some of the more fun, not to say embarrassing, pictures from the archive are not suitable for public display. But I’m happy to inflict the sci-tech oriented discoveries – starting today with these pics of my first serious astronomical telescope.

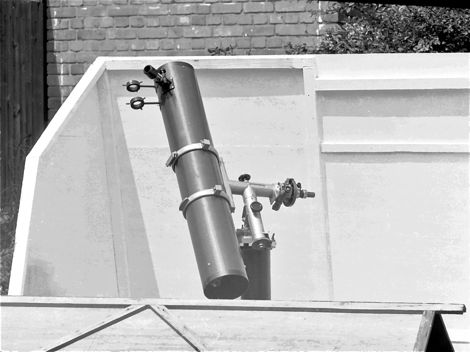

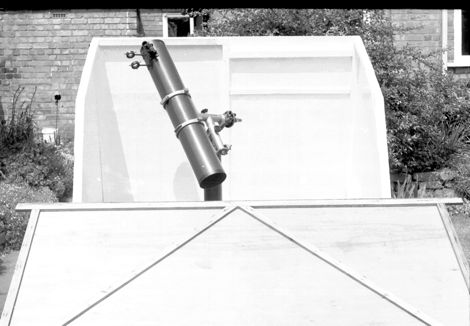

The main components were bought in 1977, and this photo of the telescope in its observatory is probably from 1979. The instrument is a classic Newtonian reflector of a design that hasn’t changed in hundreds of years. It has a 6″ primary mirror, and was built by Fullerscopes of London, the same company that made Patrick Moore’s fork-mounted 15″. The mount is a Fullerscopes Mk III German Type equatorial. The ancillaries: motor drives, plinth, finder, camera attachments, and the observatory itself are home built.

To be accurate, this was my second telescope, the first being an entirely home-built open-tube reflector in an altazimuth type cradle. Constructed almost entirely from sturdy aluminium bar stock – largely because that’s what I had – it all proved a little unwieldy. No photos survive – probably for the best.

The 6″ was mainly used for visual observations. I later added an improved synchronous motor drive to the Right Ascension (RA) axis to make the instrument more suited to astrophotography, but as that happened in 1980, just before I left home for university and ever on, that feature was little used.

Warning – Telescope building aficionados, engineers, (and all other interested readers….!) only

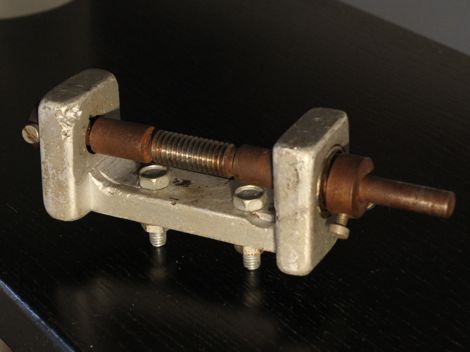

Assembling, augmenting, or building a telescope from scratch is an excellent engineering, as well as scientific, training. To save money, I purchased only the RA axis worm drive from Fullerscopes, with a view to reverse engineering it and building a copy for the declination axis. Operations to do that included aluminium casting, worm screw cutting, and making my own integrated roller ball-bearings on the worm shaft (to remove any trace of play, and hence instrument movement). Thankfully, my brother was building a model steam engine at the time, so a good selection of machine tools were available around the home.

I realise now that some of these operations were quite sophisticated engineering tasks, particularly for a 15 year old – probably why things didn’t always turn out as planned. I struggled to reproduce the 4.5″ phosphor bronze worm wheel (although the trick for cutting a worm wheel, by winding a tool-post mounted wheel into a spinning tap mounted between lathe centres, I find fascinating and elegant), and instead adapted an ex-military gun-sight for the declination axis. That said, the worm unit I’d made was better than the original, and eventually replaced it.

The RA motor connected to the drive worm via a gearbox, also homemade using mecano gears mounted in a solid block of steel, the centre of which had been milled out on the lathe and fitted with individually turned and reamed phosphor-bronze bushes. The whole drive assembly was bolted to the plinth and linked to the final worm gear on a universal joint. This all worked fine, unless the telescope was incorrectly counter-balanced, when teeth would expensively shear off the little mecano gear wheels.

Despite these set-backs, or perhaps because of them, it’s my firm belief that this activity set me up well to tackle life’s later challenges: like building my own research equipment and mending the car.

The telescope’s plinth and observatory have their own stories. I’d read somewhere that telescopes need a rock-solid mount, and that plinths mounted in concrete are superior to tripods. In the photo, you can just see the top of a 5ft x 5″ x 1/4″ steel tube, 2 ft of which is buried in a 3ft square cube of concrete. The base of the observatory is covered in paving stones laid on sand, with a gap around the central concrete block to prevent footstep vibrations reaching the plinth. The plinth was capped by a 7″ square x 3/8″ thick oxy-acetylene welded plate. I remember this well, as the welder had to commission an unusually large nozzle for the job. This was of course total overkill for a 6″ reflector; but I suspect I harbored secret fantasies of some day owning a more substantial instrument.

The observatory was made from resin bonded plywood on a pine frame. Originally designed as a run-off shed, I switched to the fold-off roof idea when the weight of the structure dictated a need for major railroad-type work adjacent to the observing area – effectively doubling the project’s footprint. In practice, a south-facing aspect and relatively low observatory walls meant the compromise solution made little impact on sky visibility. A telescope mounted permanently out of doors is always ready for action – an important consideration with UK weather – with no need to wait for thermal stabilisation of the optics or to spend time aligning the equatorial mount. It goes without saying that, like all the world’s great observatories, it was painted white.

I keep saying ‘was’, because Mount Tim was decommissioned in the early nineties, such that you’d never know the paved area had ever been anything other than a regular garden patio. Amusingly, the plinth proved immovable, save for the use of explosives, so was instead ceremoniously tipped on its side in a shallow grave. I sometimes wonder what a future Tony Robinson might make of it.

Coming back to Fullerscopes. Buying a telescope in 1976 was not like popping down the road to Curry’s and carrying it home under your arm. When my father and I first visited Telescope House on the Farringdon Road, we were greeted by Dudley Fuller in person. He’d formed the company a few years earlier by buying out the historic but failing maker of optical instruments – Broadhurst & Clarkson Ltd.

We talked about my telescope-making efforts to date, and what I needed from Fullerscopes. He was wary of my plans to attach one of his diagonal mirrors to my homemade spider using glue (EvoStick No.2 – if I must!), but we agreed a package – including a Fullerscopes spider – and placed the order. (The spider sits in the top of the telescope tube and holds a diagonally placed mirror that diverts light into the eye-piece.) A month later, I returned to man-handle this tribute to Sir Isaac through the streets of London and back to Leicester – by train.

Telescope building was still being done in a traditional way. Fuller explained that all the brass tube-work on his telescopes was hand made using Broadhurst & Clarkson’s original equipment. That meant the brass sheet was rolled on an antique mill by hand, then soldered along the seam. On my telescope, the solder seam is visible on the brass focusing mount and Barlow lens adapter tube. The economics of this, particularly on parts destined for smaller instruments like my 6″, and at a time when Japan was starting to export mass-produced alternatives, must have been unsupportable. I’m guessing that’s the reason the Farringdon road shop closed down in 2005 and Telescope House moved out of town. It looks like they’re still trading though, with Patrick Moore’s endorsement into the bargain. (Telescope House website). But they don’t seem to be making their own instruments any more – please correct me if you know different.

There’s a related and slightly surreal twist to the story here, concerning my move to London in 2000. Needing a more portable telescope for out of city viewing, I visited Fullerscopes, now the UK agent for Meade Instruments Corp. of the USA, makers of the compact Cassegrain-Maksutov telescope I was after. The odd thing was, when I got chatting to the guy who handed over the box, it turned out he had personally been involved in making the brass-work for my 6 inch reflector 24 years earlier! It’s a nice story.

Anyhow, I hope that wasn’t completely boring and self-absorbed. If nothing else, it may have given you an insight into what I was getting up to in my formative years. You know, when I should have been out doing drugs, smashing up cars, and getting my underage girlfriend pregnant – like a normal teenager 🙂

Don’t forget to check back for the next exciting edition of Out Of The Archives……